Miracle Cardi

(Fixed Bucket Coagulator)

The Miracle Cardi, a fixed bucket coagulator, accurately measures soymilk using the cumulative electromagnetic flowmeter.

By not using a measurement tank, all buckets are effectively utilized, and precise air mixing in the soymilk is achieved. The coagulant measurement is also carried out using a circulation system instead of a measurement tank system, eliminating coagulant residue in the pipes and ensuring accurate measurement.

| Type | 6 | 8 | 10 |

|---|---|---|---|

| Capacity | 120kg/h | 180kg/h | 240kg/h |

| Outer Dimensions | L1280×W1840 ×H1900mm | L1280×W2320 ×H1900mm | L1280×W2800 ×H1900mm |

| Capacitance | 1.9kW | 2.1kW | 2.3kW |

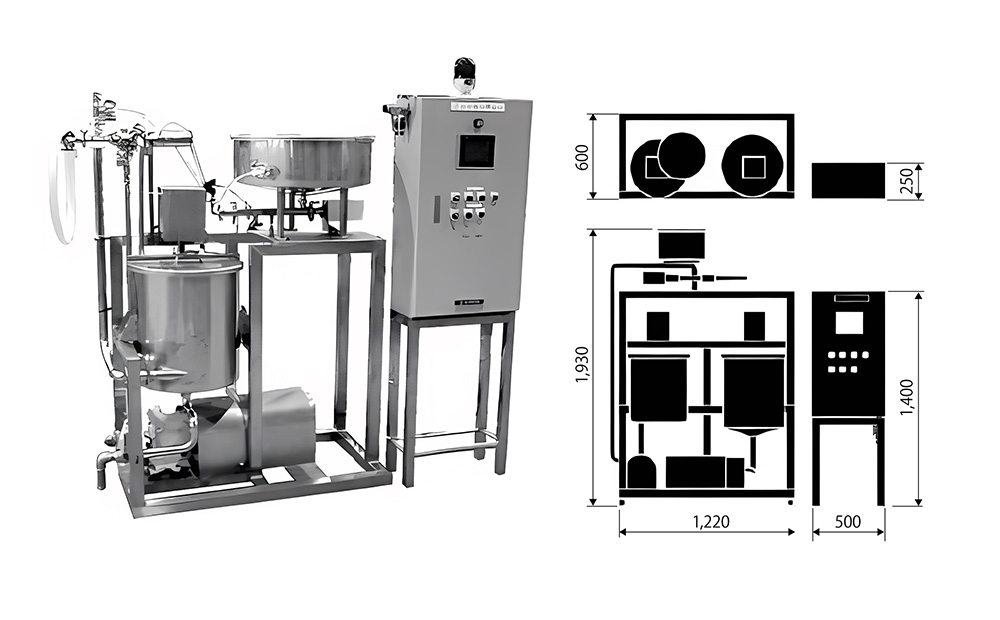

Bucket Coagulation Machine

The highly regarded bucket coagulation machine offers stable performance, allowing you to freely adjust the stirring frequency and timing according to the coagulant and product type to achieve optimal coagulation and agitation.

| Capacitance | 100 V AC 1.2kW / 200 V AC 2.25kW |

|---|

Filled Tofu Equipment

Japanese consumers are becoming increasingly uncompromising when it comes to filled tofu, demanding better flavor and longer shelf life (fewer bacteria) than ever before. Recently, products made with 100% nigari, which was previously considered difficult, are becoming mainstream.

Nigari effects soymilk instantly even under cooled condition, so it must be filled immediately after mixing with nigari.

Our company has overcome these challenges by combining our know-how in “curding” cultivated through Multi-Cardi and advanced control technology.

Furthermore, by integrating our original C.I.P cleaning device, deaerator, and boil-cool tank, we can provide the highest quality filled tofu production line.

Hot Filling Equipment

Pack the “freshly squeezed deliciousness” as it is!

High-temperature coagulated filled tofu is now possibly produced, allowing you to pack the unprecedented flavor of freshly squeezed soymilk.

- Produces delicious tofu with excellent elasticity and sweetness.

- Reduces initial and running costs, and effectively utilizes factory space without soymilk cooling equipment.

- Shortens production time as soy milk cooling process is not required.

- High-temperature filling minimizes contamination by bacteria and improves hygiene.

New Cardi

Takai’s compatible model to emulsified nigari!

- High quality

Smooth and elastic delicious nigari tofu can be made from high-temperature soymilk. - Unique and Special

Can blend various coagulants, including commercially available emulsified nigari.(Optional) - Economical

Can minimize the cost increase of coagulants. - Simple

No need for high-speed agitation equipment for coagulation allows maintenance-free.

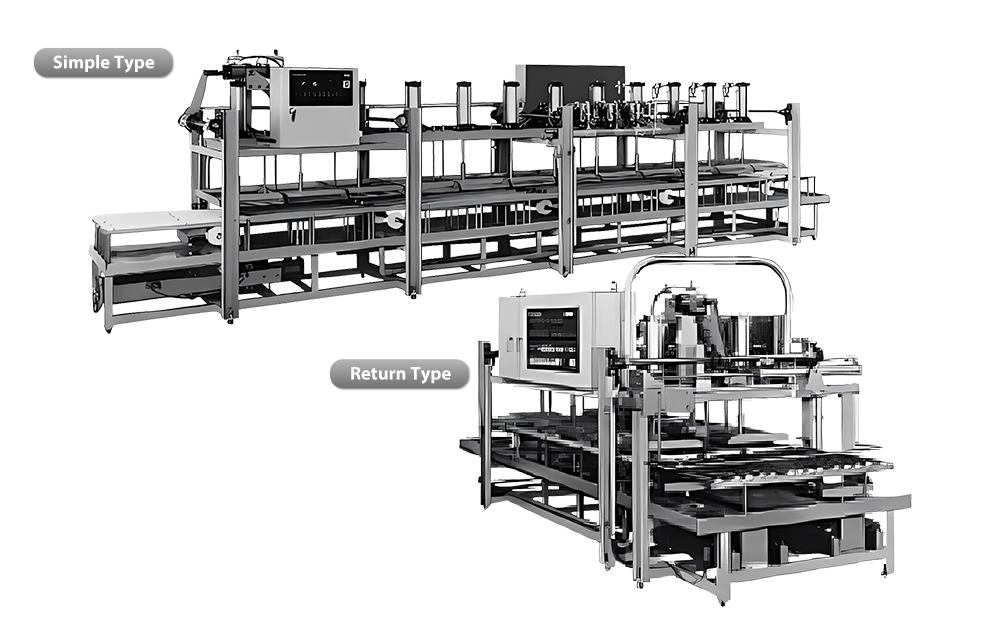

Air Presser

You can freely adapt to your unique forming box shapes and processes.

This equipment takes into consideration the essential cleaning and maintenance.

Additionally, the return-type presser has the same entrance and exit for the forming box, which can be very efficient depending on the workflow and factory layout.

Cylinder pitch P = B + 50

Forming box size: Long side A / Short side B

| L | P x (Cylinder body + 1)+B/2+60 |

|---|---|

| M | A+2 |

| Capacitance | Single-phase 100 V (Cylinder body +2) × 50 |

Air Drainer

The air drainer is a water draining machine using an air cylinder, which allows for easy vertical movement of the press plate and adjustable pressure.

Curding Barrel, Casters,

and Mixing Plate

The curding barrel generates an even swirling flow, the agitation and coagulation it produces makes uniform curd.

| Diameter | Height | Volume |

|---|---|---|

| φ480 | 480 | 87 ℓ |

| φ510 | 480 | 98 ℓ |

| φ540 | 480 | 110 ℓ |

| φ600 | 480 | 135 ℓ |

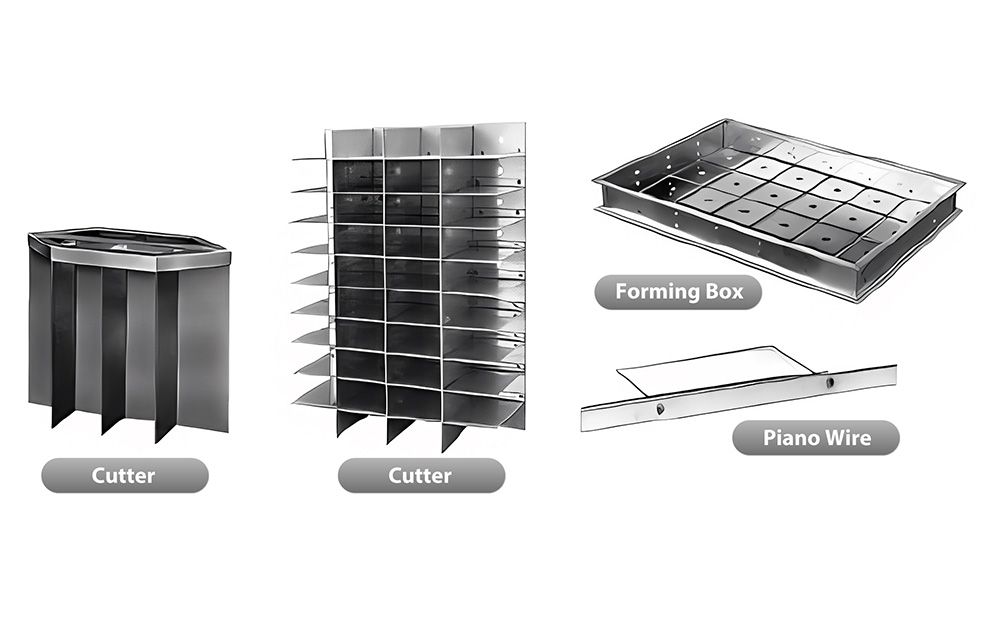

Forming Box, Cutter,

and Piano Wire

We offer a variety of forming boxes considering the product and manufacturing process.