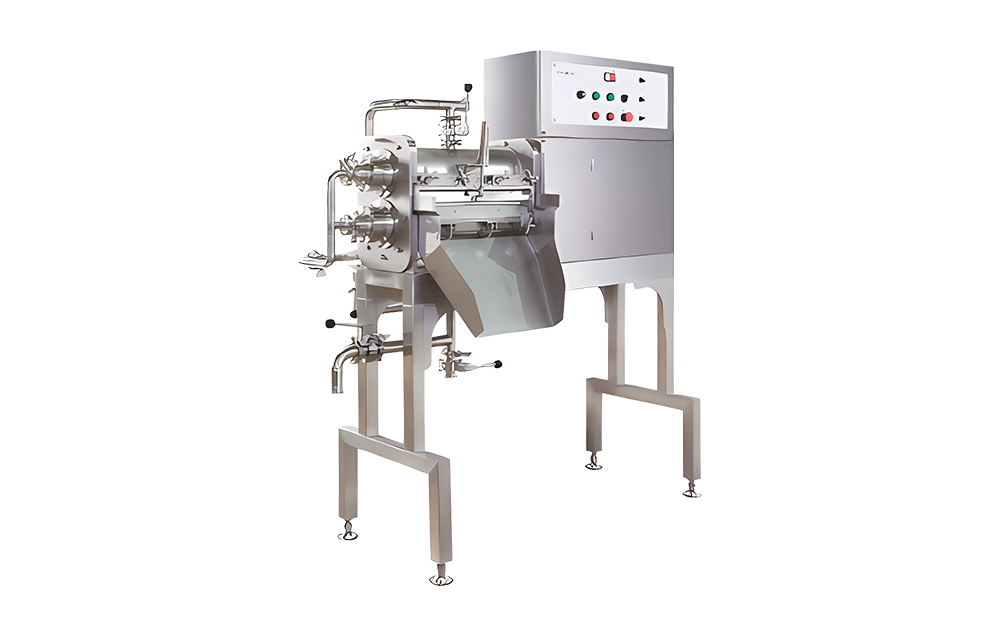

Miracle Grinder

“Grinder without grinding stone” Soybeans can be ground to four different grain sizes!

All contact parts are made of stainless steel and can be disassembled, so it is hygienic.

Moreover, this model contributes to no abrasive grains, no damages to the screen (squeezer), and securing longevity!

What you must be pleased is that running costs (energy-saving) are kept to a minimum.

| Capacity (raw soybean) | 120~600kg/h |

|---|---|

| Outer Dimensions | L1050xW600xH800mm |

| Capacitance | 200V , 11.0kW, 15HP |

Miracle 8 Eight α

This compact squeezer offers both power and technique!

Compact and simple yet offers excellent performance. For instance, long time and continuous operation is possible. Air pressure adjustment is stably operates as well. Also, submerged squeezing allows you to produce tofu without deformer.

Do not worry about the treatment as well! Easy adjustment to optimal conditions for various cases, circulation washing and easy maintenance must assist your production dramatically. Additionally, this model accomplishes the minimum amount of bean curd residue in this industry.

| Capacity | 60~300kg/h |

|---|---|

| Outer Dimensions | L1350×W500×H1500mm |

| Capacitance | 200V , 2.4kw |

Miracle Cardi

(Fixed Bucket Coagulator)

The Miracle Cardi, a fixed bucket coagulator, accurately measures soymilk using the cumulative electromagnetic flowmeter.

By not using a measurement tank, all buckets are effectively utilized, and precise air mixing in the soymilk is achieved. The coagulant measurement is also carried out using a circulation system instead of a measurement tank system, eliminating coagulant residue in the pipes and ensuring accurate measurement.

| Type | 6 | 8 | 10 |

|---|---|---|---|

| Capacity | 120kg/h | 180kg/h | 240kg/h |

| Outer Dimensions | L1280×W1840 ×H1900mm | L1280×W2320 ×H1900mm | L1280×W2800 ×H1900mm |

| Capacitance | 1.9kW | 2.1kW | 2.3kW |

On-line Coagulation Inspection Equipment

Using Takai’s original technology, this equipment instantly detects and removes uncoagulated products through non-contact methods.

Again, thanks to Takai’s original technology, not only tofu, but also various food items such as yogurt and jelly in containers can be instantly detected and removed if uncoagulated, all without direct contact.

- It is a non-contact, non-destructive inspection system.

- Significantly reduces inspection errors due to automation.

- Can be integrated into conveyor lines.

- Easy operation with color touch panel.

- Applicable to packaged products of tofu and other gel-like foods.

- Data storage is possible, making it convenient for managing soybeans and manufacturing conditions.

- Product data can be saved, which is helpful for promoting standards like ISO9000.