Boiling & Cooling Tank

By maximizing the benefits of the circulation system in the temperature-sensitive boil & cool process, the impact on product quality is minimized.

Additionally, cycle times for each process can be displayed as data on the touch panel screen.

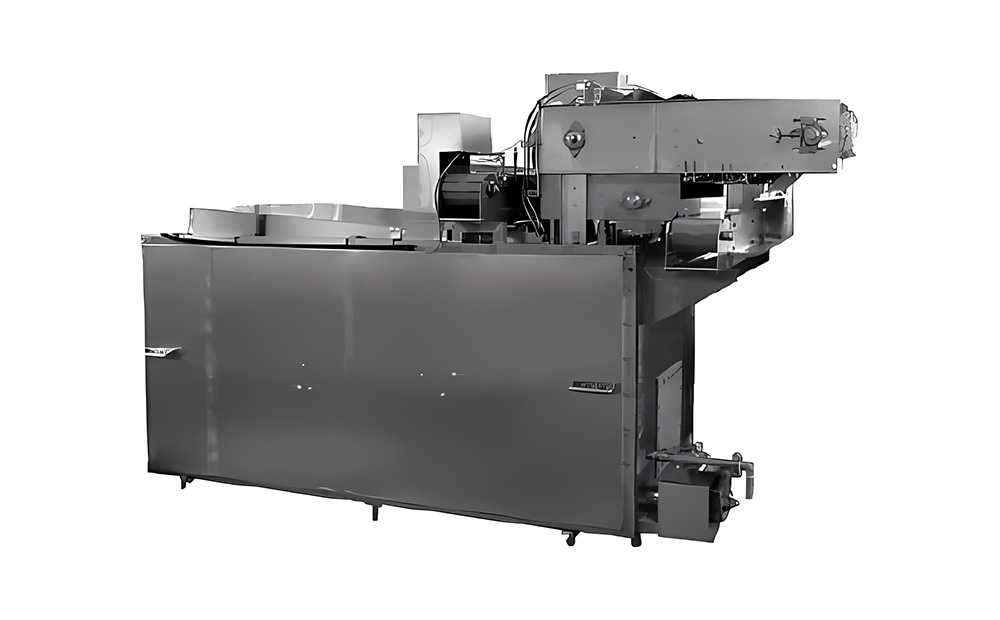

Hot Pack Water Tank

The Hot Pack secondary water tank adopts a highly efficient cooler with excellent cooling effects by devising the distribution and circulation of cooling water and utilizing a unique internal structure (US patented).

Mini Boil

- No temperature variation compared to steam type.

- No deformation of tofu packs compared to steam type.

- Can be connected to an existing cooling water tank.

- Compact design that does not take up much space.

- Can be used for heating sterilization tanks, filled tofu, and more.

| Outer Dimensions | W3400×D1600×H2000mm |

|---|---|

| Capacitance | AC200V , AC 0.2kW |

Circulating Cooling Tank

Water entering from the bottom cools the tofu uniformly through the perforated plate. Warmed water is drained from the upper end of the pipe, creating an efficient flow of cooling water in the tank.

Cooling Tank

The tank has rounded edges, an easy-to-clean drainage hole, and an overflow pipe attachment hole, providing a sanitary water tank.

It comes in the same dimensions as the circulating cooling tank, with a single and double-tank version.

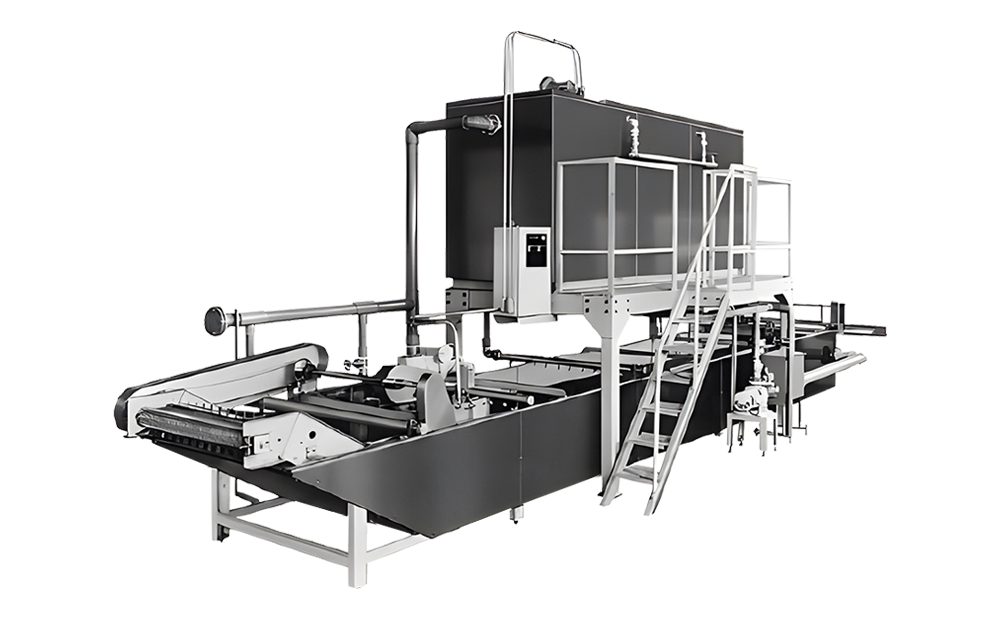

Automatic Cooling Tank

Tofu is placed in the inlet side of the tank, which has sufficient depth and space for handling a forming box.

Submerged tofu is slowly transported to the outlet side by the drive net at the bottom.

The drive net surface is flat, making it less likely for tofu to be damaged.

| Capacitance | 200V , AC 0.4kW |

|---|